Connect with us

* Required fields

* Required fields

The rapid deployment of an uncrewed survey vessel (USV) played a critical role in helping to salvage cargo from a heavy transport vessel which ran aground with almost 300t of fuel oil on board during one of the worst typhoons to hit Taiwan in decades.

At the request of the Taiwanese government and within 24 hours, Sulmara had mobilised a WAM-V 16 USV and a team of survey specialists to assist in the emergency fuel recovery operation for the heavy transport vessel, Yu Zhou Qi Hang.

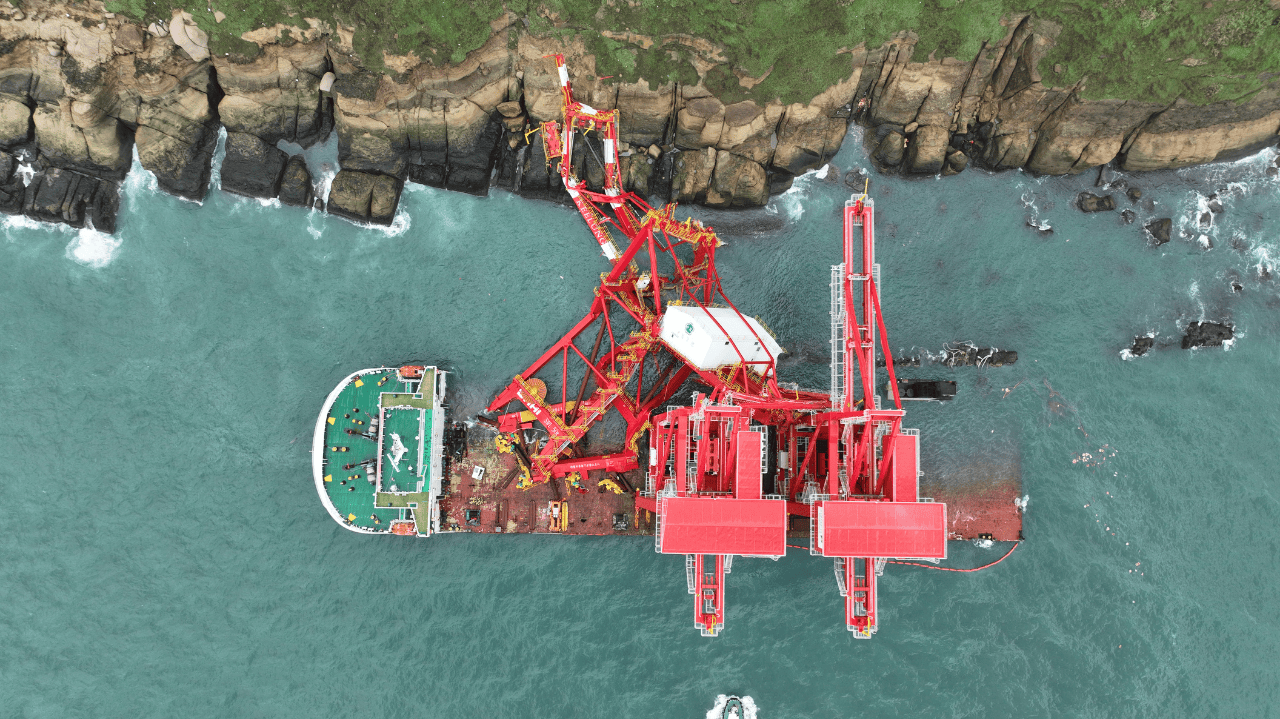

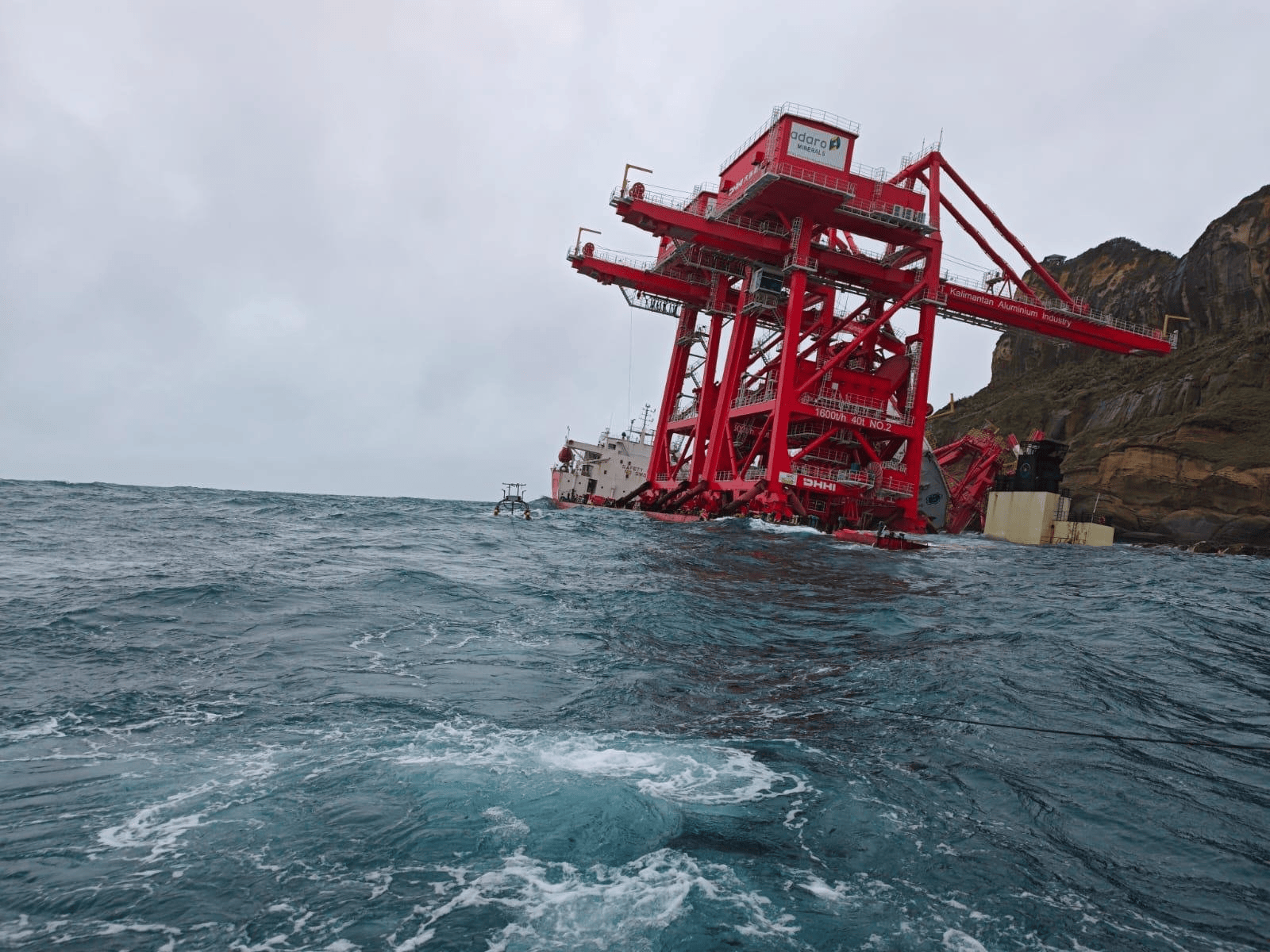

The 143m-long vessel, which was also carrying three gantry cranes, lost power off the coast of Taiwan on October 29 amid Typhoon Kong-rey. While all 17 crew members on board were safely recused by a Coast Guard vessel, poor weather conditions and unknown seabed hazards in shallow waters complicated the safe removal of the fuel after the ship ran aground in a Taiwanese national park.

With the Maritime Port Bureau and the Taiwan Environmental Protection Department facing the urgent challenge of ensuring the fuel was extracted safely to prevent further environmental impact, Taiwanese marine contractor Dong Fang Offshore was called upon to deploy the Orient Constructor, a vessel capable of lifting salvage equipment and pumps onto the wreck.

However, the operation presented high risks because manoeuvring the Orient Constructor close to the grounded vessel in adverse weather and shallow waters was further complicated by limited information on the potential subsea hazards below the keel.

To mitigate the risk of damage to the Orient Constructor and ensure safe navigation in the shallow waters, Dong Fang Offshore worked alongside Sulmara to conduct a complex seabed survey.

Denny Wang, Survey Operations Supervisor for Sulmara, led the Taiwan-based team which included USV pilot and engineer, Sathesh Kumar, surveyor David Chandra Wibowo, and marine operations supervisor, Eddie Wo.

Wang said: “It was a huge challenge. While the salvage operation took place a week after the typhoon, November is not the ideal season for carrying out survey work and particularly for an incident like this. The severe weather conditions - the wave height and prevailing wind - meant that traditional methods of obtaining the data from the seabed using a small boat with personnel on board weren’t workable.

“This USV is a very shallow-drafted vessel which could manoeuvre around this challenging environment. However, because of the weather conditions, we couldn’t operate the USV in the typical way by releasing her and letting her sail alone. We had to ensure we could launch and deploy the vessel safely.

“We had historical data from previous work on the site so we knew factors like water depth variants and they made for safe water for the USV. We were able to apply that data while our marine operations supervisor came up with an alternative methodology for ensuring a safe operation which included connecting a towing line to the USV as back up in case anything happened, and we could bring her back.

“Our Marine Operations Supervisor stayed on board the support vessel to monitor the USV operation, and we also deployed survey personnel on the Orient Constructor to support high-accuracy positioning and seabed monitoring during USV operations.”

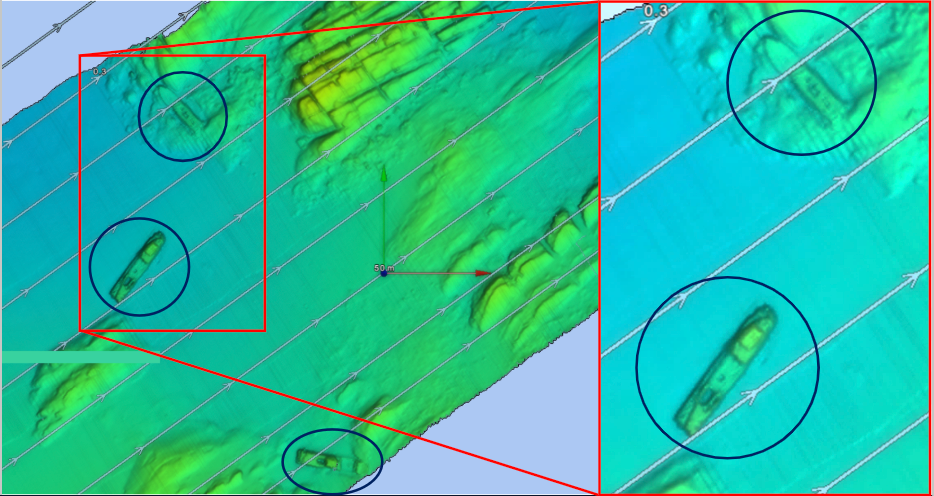

Sulmara equipped a WAM-V 16 USV with a multibeam echosounder (MBES), a sensor used to map the seabed. The data collected was used to independently verify and cross check existing seabed data, instilling confidence to proceed.

“The Orient Constructor was about 30 metres from the Yu Zhou Qi Hang with around nine metres of water under the keel which fortunately provided more than three metres of safe working water depth,” said Wang.

As a result, Sulmara's quick deployment and use of uncrewed systems ensured the safe collection of high quality seabed bathymetric data, minimising risks to both the vessel and personnel while the team’s responsiveness and resilience allowed the operation to progress despite the challenging conditions.

Sulmara also worked closely with its clients onshore by reviewing and advising on the data which enabled the team to navigate safely and efficiently, ensuring a successful fuel removal operation.

Within just two days, the WAM-V 16 was demobilised after safely completing its mission. The rapid response also enabled Dong Fang Offshore to complete the salvage operations within a week of arriving on site.

Weng said: “We’re proud of our support in the operation and our collaboration with Dong Fang Offshore who we’ve worked with before. It was a huge challenge because we had to find space for our USV and had supporters working day and night.

“On initial assessment of the situation, we didn’t think we could collect data within a week because there wasn’t any weather window, and the site is not an area we typically work in. But after carrying out an assessment and then assessing the risks again – sea state and wave frequency - the team believed we could do it safely.

“Personally, I didn’t expect to be doing something for the Government. I know we can help protect the environment because that’s what we do through the renewable energy and offshore wind projects we work on. But this was different. As someone said, the support efforts in the operation helped the country to avert a major environmental incident.”