Connect with us

* Required fields

* Required fields

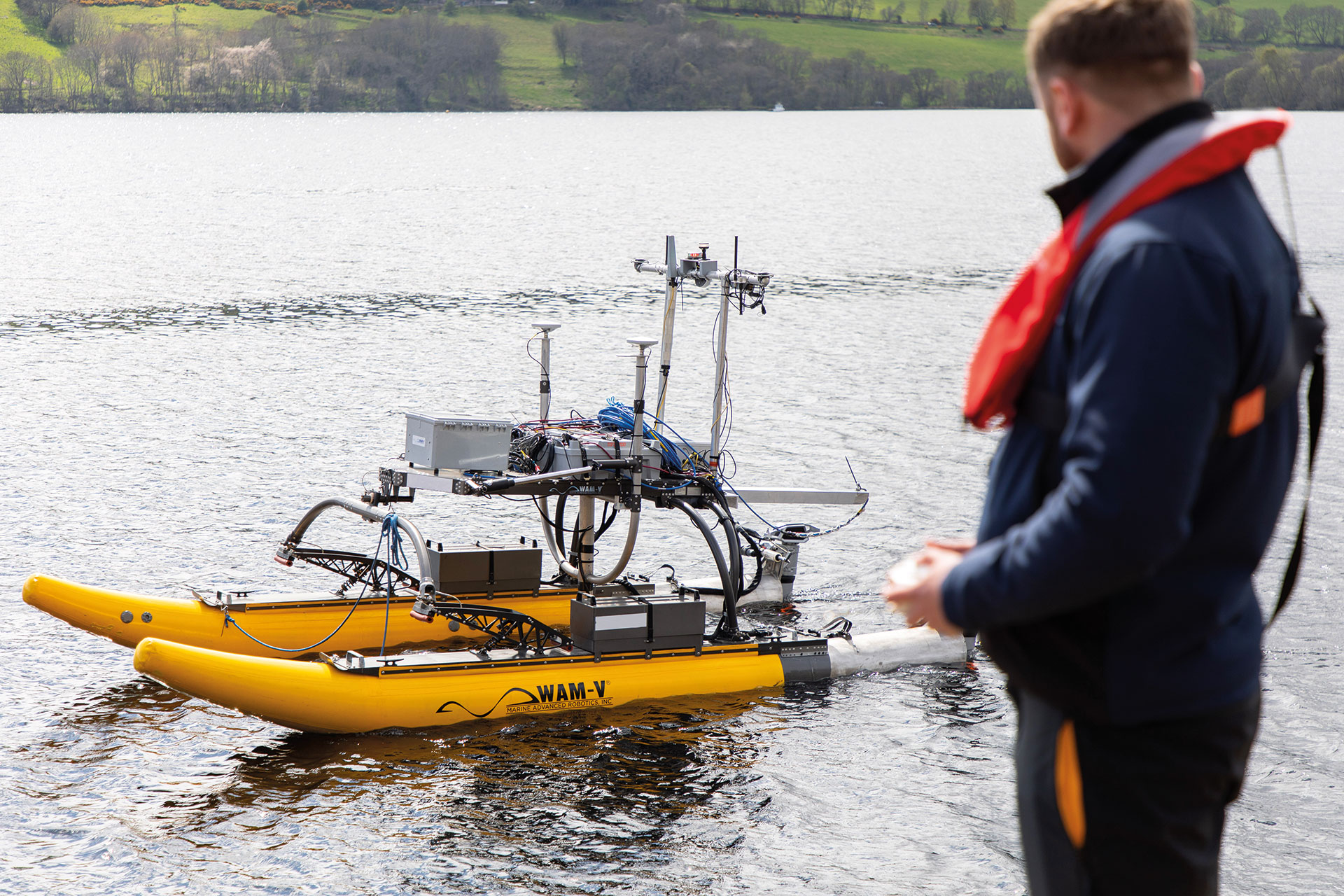

As well as being cheaper and easier to deploy, they can be operated remotely, with rapid data transfer, enabling delivery of results earlier in the site investigation process, or critical asset inspection decisions to be made sooner.

We are able to collect full hydrographic and geophysical datasets in nearshore environments around the world with no-one offshore, all supported from our Remote Operations Centre.

Development and improvement of technology is at the heart of our business.

We innovate to meet client requirements, but this requires early engagement and shared goals with stakeholders across our industry. We make sure that we fail quickly, and develop stronger, more capable solutions as a result - helping us decarbonise data acquisition and push towards net-zero.